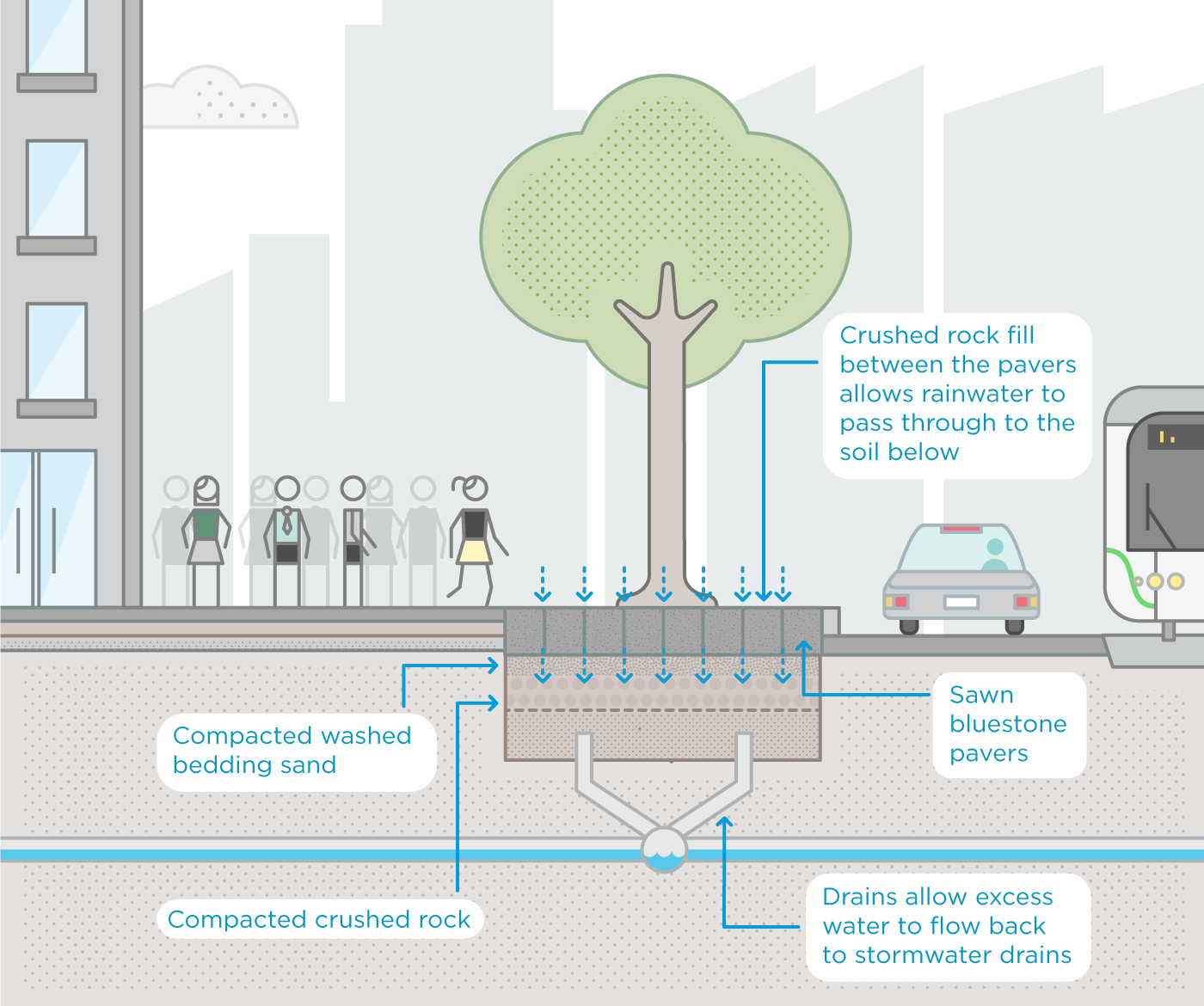

Permeable bluestone pavement

Melbourne's iconic bluestone footpaths are being adapted to create a more permeable surface and improve tree health.

Since the early 1980s the City of Melbourne has been upgrading the footpaths in the central city from asphalt to sawn bluestone pavers.

Bluestone paving is a defining element of Melbourne’s character. It is a durable and long-lasting surface that improves footpath accessibility, especially for disabled community members.

However, standard bluestone paving is impermeable or sealed – it does not allow water to pass through. Rainwater collected on the paving flows into the drains and out to the Yarra River. It gathers litter and pollution along the way.

We trialled a new approach to installing permeable bluestone, that allows rainwater to soak down between the pavers. This improves soil moisture and waters the adjacent trees.

Since the successful Collins Street trial, we have installed permeable bluestone paving in several locations across the central city.

What benefits has the permeable bluestone paving provided?

- Increased water flow to trees through passive irrigation.

- Improved soil volume and moisture for over 40 trees.

- Reduced the amount of rainwater flowing into the stormwater drains.

and infiltration